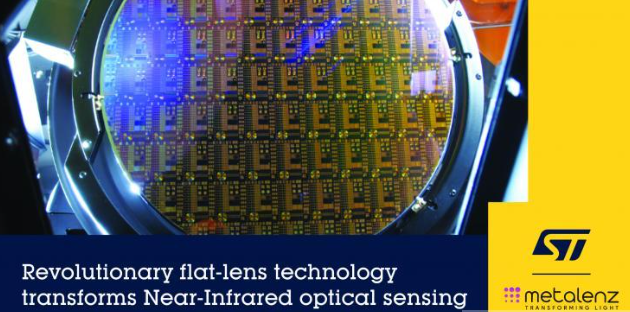

ST and Metaenz, a pioneer in the design and commercialization of metasurface technology, have jointly announced a technology co-development and licensing agreement under which ST will develop manufacturing processes for Metalenz's ultra-optical technology to produce next-generation optical sensors for smartphones, consumer electronics, medical and automotive. Metalenz was spun out of the research group of Harvard University Professor Federico Capasso, the inventor of the technology. The breakthrough technology is expected to be ready for mass production by the end of the year.

Metalenz's versatile metasurface optics enable new types of optical sensors to be used in consumer electronics such as next-generation smartphones, as well as in medical devices and automotive systems. For example, cameras based on this new flat lens technology can collect more light, improve the brightness of images, and produce images that are comparable to or even better than traditional refracting lenses. At the same time, lower power consumption and smaller size.

By integrating Metalenz's metasurface optics technology into the existing diffractive optical element manufacturing process at the Crolles 300mm wafer fab in France, ST is leveraging its leadership in the fast-growing near-infrared (NIR) optical sensor market. Today, ST is the market leader in ToF proximity detection and ranging sensors, with more than 1 billion shipments.

Eric Aussedat, Executive vice president and general manager of ST's Imaging Business group, said: "With its advantages in power consumption, energy efficiency and performance, multifunctional optical technology could be a game-changer for consumer electronics such as smartphones, as well as next-generation optical sensors for medical and automotive applications. By integrating Metalenz's advanced technology with our know-how to process the chips in a state-of-the-art 300mm manufacturing facility at the Crolles facility, this partnership will help ST continue to provide customers with innovative advanced optical sensing solutions."

Dr. Rob Devlin, CEO and co-founder of Metalenz, said, "We are excited to partner with an industry leader like ST. The optical technologies developed by Metalenz complement ST's advanced manufacturing capabilities and market position. We have adopted a fabless business model so that we can focus on innovating and designing groundbreaking optical technologies to revolutionize optical sensors for smartphones and cars. The collaboration with ST allows us to expand our product range while taking full advantage of ST's massive capacity to apply Metalenz technology within ST products, taking ST's product differentiation to a new level."

Today's mobile phone technology is changing rapidly, trying to squeeze more and better features into a small body. But lenses have remained largely unchanged since the Middle Ages. Now, this is changing, as metasurface optics technology has led to a new class of lenses that work very differently from traditional lenses. Instead of a large spherical lens, metasurface optics integrates multiple complex optical functions on a single flat layer, which reduces the size of each lens while also reducing the number of lenses required for the lens, greatly reducing the lens size, number of components, assembly complexity, and overall cost.

The metasurface optics technology developed by Metalenz complements and complements ST's advanced manufacturing capabilities. St integrates semiconductor manufacturing processes with optical technology to build modulated diffractive wavefront layers on metasurfaces using advanced lithographic masks in semiconductor fabs. Like silicon-based chips, metasurface planar lenses are also machined in a clean room, using the same semiconductor manufacturing techniques as chips. These planar lenses have nanostructures that are one-thousandth the diameter of a human hair and are able to refract light in just the right way, achieving the same function as complex multi-lens refracting lens systems on a single layer.

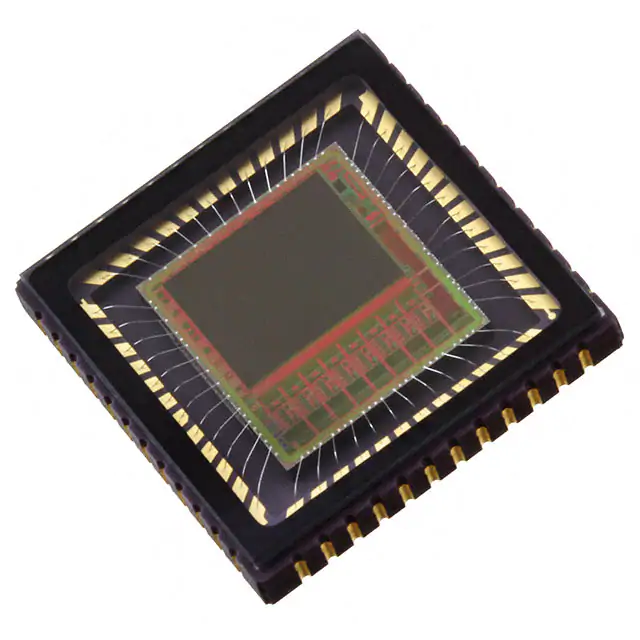

The initial target market for this technology is the rapidly growing NIR near infrared market. NIR wavelengths are used in all 3D sensors, such as facial recognition, camera autofocus, miniature lidar, and AR/VR depth maps, which have become standard on today's smartphones. Given these benefits, optical lenses made in semiconductor fabs may one day be as widely used as traditional refracting lenses.

The Products You May Be Interested In

|

TPCM-2.4-5 | CMC 2.41MH 5A 2LN TH | 383 More on Order |

|

62054-P2S02 | XFRMR TOROIDAL 15VA CHAS MOUNT | 107 More on Order |

|

62051-P2S02 | XFRMR TOROIDAL 15VA CHAS MOUNT | 184 More on Order |

|

62044-P2S02 | XFRMR TOROIDAL 10VA CHAS MOUNT | 336 More on Order |

|

62035-P2S02 | XFRMR TOROIDAL 7VA CHAS MOUNT | 369 More on Order |

|

62034-P2S02 | XFRMR TOROIDAL 7VA CHAS MOUNT | 441 More on Order |

|

62025-P2S02 | XFRMR TOROIDAL 5VA CHAS MOUNT | 218 More on Order |

|

62021-P2S02 | XFRMR TOROIDAL 5VA CHAS MOUNT | 281 More on Order |

|

62012-P2S02 | XFRMR TOROIDAL 3.2VA CHAS MOUNT | 178 More on Order |

|

70074K | XFRMR TOROIDAL 35VA THRU HOLE | 380 More on Order |

|

70031K | XFRMR TOROIDAL 7VA THRU HOLE | 481 More on Order |

|

70024K | XFRMR TOROIDAL 5VA THRU HOLE | 486 More on Order |

|

70015K | XFRMR TOROIDAL 3.2VA THRU HOLE | 421 More on Order |

|

70014K | XFRMR TOROIDAL 3.2VA THRU HOLE | 309 More on Order |

|

70003K | XFRMR TOROIDAL 1.6VA THRU HOLE | 140 More on Order |

|

62015-P2S02 | XFRMR TOROIDAL 3.2VA CHAS MOUNT | 210 More on Order |

|

70025K | XFRMR TOROIDAL 5VA THRU HOLE | 226 More on Order |

|

62024-P2S02 | XFRMR TOROIDAL 5VA CHAS MOUNT | 268 More on Order |

|

70064K | XFRMR TOROIDAL 25VA THRU HOLE | 2293 More on Order |

|

70005K | XFRMR TOROIDAL 1.6VA THRU HOLE | 401 More on Order |

|

AC1200 | CURR SENSE XFMR 200A T/H | 119 More on Order |

|

AC1050 | CURR SENSE XFMR 50A T/H | 409 More on Order |

|

AC1015 | CURR SENSE XFMR 15A T/H | 287 More on Order |

|

AC1025 | TRANSFORMER CURRENT 25.0 AMP | 235 More on Order |

Semiconductors

Semiconductors

Passive Components

Passive Components

Sensors

Sensors

Power

Power

Optoelectronics

Optoelectronics