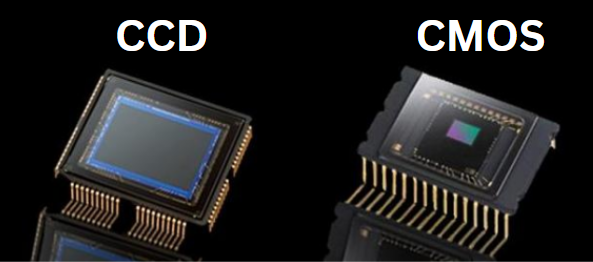

The adoption of imaging systems in industrial applications is rapidly growing, fueled by innovations in image sensor technology and advancements in computing power and high-speed data interfaces. Imaging systems are now widely used in areas like wiring inspection, traffic monitoring, surveillance, and medical and scientific imaging. Progress in CCD and CMOS technologies has led to enhanced performance, faster readout speeds, and higher resolution. Understanding the differences between these two sensor platforms is key to selecting the most appropriate solution for various applications.

The development of electronic imaging technology began in the 1960s when Nobel laureates Boyle and Smith developed the first CCD. These devices operate by exploiting the intrinsic ability of doped silicon to convert photons into electrons, measuring light intensity through pixel-level charges. The main architectural advantage of this design lies in its simplicity, as the entire pixel area is used for detecting photons and storing charges, offering maximum signal levels and supporting a high dynamic range.

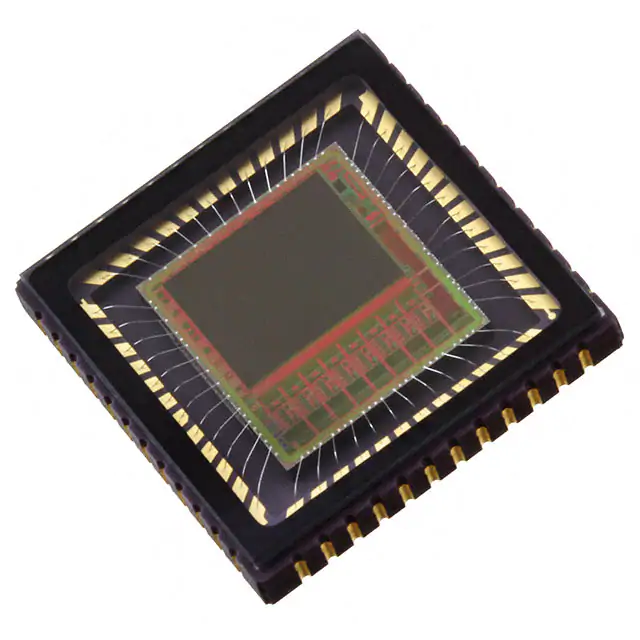

The pixel area enables charge transfer to a limited output node, where it's converted into voltage. Over time, this design evolved into Interline Transfer CCDs with pixel-level electronic shutters, removing the need for mechanical shutters in cameras. CCDs today are made with specialized semiconductor processes for imaging and require external circuits to convert analog signals to digital. They are known for efficient electronic shutters, wide dynamic range, and superior image uniformity.

Unlike CCDs, CMOS image sensors utilize mainstream semiconductor manufacturing processes, like those for logic chips and microprocessors, offering advantages such as integrating digital processing directly into the chip. CMOS sensors place transistors in each pixel (or group) for charge-to-voltage conversion, enabling faster, more flexible image readout by transmitting voltage rather than charge. Advanced processing can be built into the chip, allowing the output of fully processed JPEG images or even H.264 video streams.

Historically, CCD image sensors have provided better imaging performance than CMOS devices. However, recent advancements have significantly narrowed the gap, and the image quality of CMOS sensors is now suitable for many applications. This is evident in the latest generation of CMOS sensors used for industrial imaging, such as ON Semiconductor’s PYTHON CMOS sensor series.

Although some CCD sensors may still outperform certain imaging parameters, the image quality of the PYTHON series is adequate for applications like online inspection, traffic monitoring/tolling, and motion analysis. This highlights the additional performance advantages of CMOS technology, such as faster frame rates, lower power consumption, and Region of Interest (ROI) imaging—each of which is critical for enhancing productivity and supporting these applications.

Due to these inherent advantages, some predict that CCD image sensors will eventually be phased out as CMOS technology continues to advance and eventually surpass CCDs in all aspects. Nevertheless, CCD and CMOS technologies will undoubtedly continue to evolve, with CCDs maintaining certain performance advantages in specific applications that demand the highest imaging performance.

While image uniformity has improved with CMOS technology, the highest levels of performance are still found in CCD applications. This is a direct result of the architecture: whereas CMOS sensors feature thousands of individual amplifiers (one for each row, or even each pixel), CCDs route charge from the pixel to a single amplifier, allowing sensor readout without amplification variation. High image uniformity is critical for applications such as medical and scientific imaging, as well as precision product inspection, where quantitative results depend on clear, unprocessed images. Additionally, CCDs tend to maintain better uniformity when scaled to higher resolutions and larger optical formats compared to CMOS sensors.

The analog nature of CCD designs also allows for customization and optimization of imaging characteristics for specific end-user applications. For example, in astronomical imaging, camera manufacturers can optimize the sensor’s capabilities (e.g., extending dynamic range) at the expense of certain features, such as anti-blooming, which may not be as critical for the application. Other scientific imaging applications benefit from the low dark current offered by CCDs, enabling exposure times of over an hour to detect faint signals.

Given these architectural advantages, companies like ON Semiconductor continue to invest in CCD technology and products. A notable example is a newly announced CCD technology platform, which combines Interline Transfer CCD imaging performance with the ultra-low sensitivity achievable through Electron Multiplying CCD (EMCCD) output.

The combination of Interline Transfer EMCCD allows a single camera to capture part of a scene (e.g., a dimly lit alley) under extremely low light conditions (as low as moonlight or even starlight), while another part of the scene is brightly lit (e.g., under streetlights). This capability enables a single camera to capture images from daylight to starlight levels, a feature unique to CCD technology, leveraging the charge multiplication capabilities of EMCCD output—a characteristic that CMOS devices, constrained by their operating voltage range, cannot offer. Products incorporating this technology offer 1080p resolution at 30 fps, making them ideal for low-light surveillance, scientific imaging, and medical imaging.

While comparisons between CCD and CMOS technologies may lead some to seek a definitive “winner,” such a conclusion would be unfair to both, as each technology is unique and offers distinct advantages to end-users. Although CMOS-based products are clearly gaining wider adoption, CCD image sensors retain advantages in specific areas, making them better suited for certain applications. Rather than searching for the “best” technology, users should focus on the key performance parameters of their specific end applications and match those needs to the characteristics and capabilities of available products.

In some cases, products based on one technology may provide the best fit. However, in situations where the choice is not as clear-cut, it is especially beneficial to work with a company that offers both technologies to ensure an objective assessment. By accessing a broad portfolio of products based on both CCD and CMOS technologies, end users can identify and select the product that truly meets the requirements of their specific applications, ultimately emerging as the real winners.

The Products You May Be Interested In

|

FLTR75V05 | LINE FILTER 75VDC 5A TH | 384 More on Order |

|

CLP0228FPXXXZ01A | AC/DC CONVERTER 28V 200W | 417 More on Order |

|

CP2500DC54-PEZ | DC/DC CONVERTER 54V 2500W | 498 More on Order |

|

ESTW025A0F41-SZ | DC DC CONVERTER 3.3V 83W | 369 More on Order |

|

APTH006A0X4-SR | DC DC CONVERTER 0.6-3.63V 22W | 398 More on Order |

|

EVK011A0B41Z | DC DC CONVERTER 12V 132W | 493 More on Order |

|

EHHD020A0F641-HZ | DC DC CONVERTER 3.3V 66W | 285 More on Order |

|

HC006A6A61Z | DC DC CONVERTER 5V 33W | 337 More on Order |

|

QRW025A0F841Z | DC DC CONVERTER 3.3V 83W | 288 More on Order |

|

QW075A1 | DC DC CONVERTER 5V 75W | 253 More on Order |

|

QHW100D71 | DC DC CONVERTER 2V 40W | 474 More on Order |

|

LW015A1 | DC DC CONVERTER 5V 15W | 380 More on Order |

|

LAW005B | DC DC CONVERTER 12V 5W | 363 More on Order |

|

JW030A1-M | DC DC CONVERTER 5V 30W | 426 More on Order |

|

JHW050FG | DC DC CONVERTER 3.3V 2.5V 50W | 228 More on Order |

|

HW010A0F1 | DC DC CONVERTER 3.3V 33W | 126 More on Order |

|

ATH016A0X3 | DC DC CONVERTER 0.8-3.6V 58W | 147 More on Order |

|

QBVW025A0B964Z | DC DC CONVERTER 12V 300W | 321 More on Order |

|

MVT040A0X43-SRPHZ | DC DC CONVERTER 0.45-2V 80W | 452 More on Order |

|

KHHD010A0A41-SRZ | DC DC CONVERTER 5V 50W | 205 More on Order |

|

APTH006A0X4-SRZ | DC DC CONVERTER 0.6-3.63V 22W | 122 More on Order |

|

UJT035A0X43-SRZ | DC DC CONVERTER 0.51-3.63V | 299 More on Order |

|

QHHD019A0B41-HZ | DC DC CONVERTER 12V 225W | 1367 More on Order |

|

APTH003A0X-SRZ | DC DC CONVERTER 0.6-3.6V 10W | 1536 More on Order |

Semiconductors

Semiconductors

Passive Components

Passive Components

Sensors

Sensors

Power

Power

Optoelectronics

Optoelectronics